Key Machines

Latest News

Cooking Oil Production Line

FFB (Fresh Fruit Bunch) of Oil Palm into CPO (Crude Palm Oil) Oil Mill Plant

Sinoder Group Supply Complete FFB (Fresh Fruit Bunch) of Oil Palm into CPO (Crude Palm Oil) Threshing & Extraction Processing & Refining & Fractionation Machinery and Solution with Full Around Technology and Service!

We're here to help: Easy ways to get the answers you need.

Product Introduction

Sinoder Group Supply Complete FFB (Fresh Fruit Bunch) of Oil Palm into CPO (Crude Palm Oil) Threshing & Extraction Processing & Refining & Fractionation Machinery and Solution with Full Around Technology and Service!

Palm oil is extracted from fresh fruit bunches (FFB) by a mechanical process, where a mill commonly handles 2.5 to 150 MT per hour of FFB.

The quality of crude palm oil depends on the care taken after harvesting, particularly in the handling of the FFBs and the process adopted.

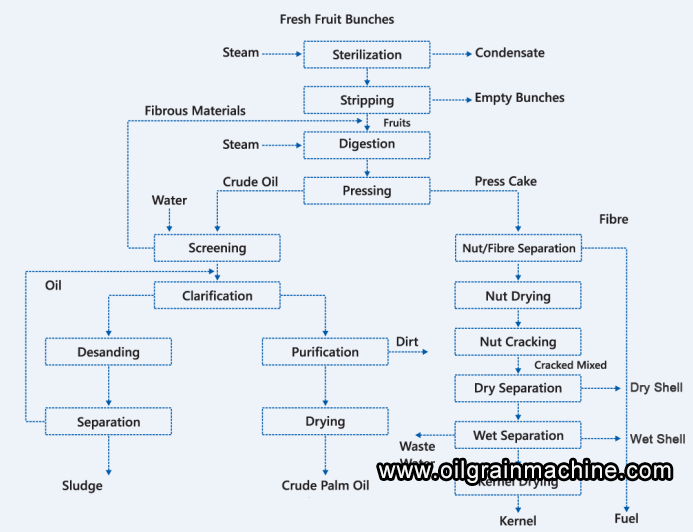

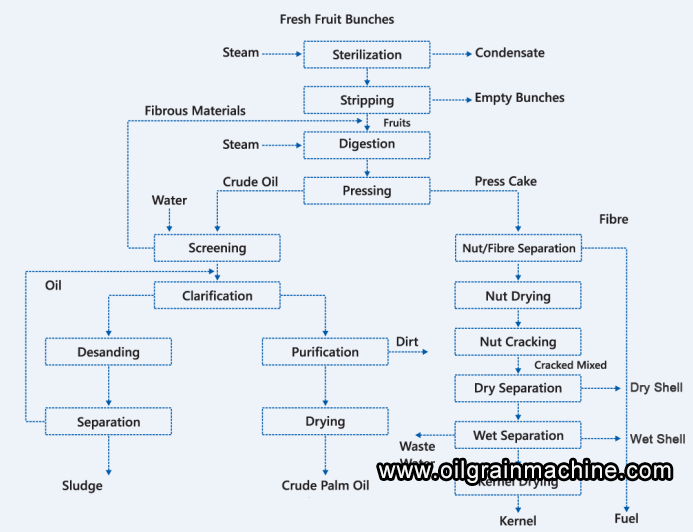

A palm oil mill produces crude palm oil and kernels as primary products and biomass as secondary product. The capacity of mills varies between 2.5 - 150 MT FFB/hr. A typical mill has many operational units as shown in Figure 2. This comprises of sterilization, stripping, digestion and pressing, clarification, purification, drying and storage. For the kernel line, there are steps such as nut/fiber separation, nut conditioning and cracking, cracked mixture separation, and kernel drying and storage. The dried kernels are often sold to palm kernel crushers for extraction of crude palm kernel oil. In some integrated plants, kernel crushing facilities exist side by side in the same complex.

Palm Oil Mill Processing Line

Palm bunch reception is the primary processing of crude palm oil processing machine. It makes preparation for raw material processing and treatment.Palm bunch reception process is finished at loading ramp. This loading ramp makes palm fruit unloading, cleaning, storage platforms, adopting all hydraulic segmented discharge.Palm bunch reception section make primary preparation of crude palm oil pressing, and enable processing of palm bunch efficiently.

Collecting the ripe fresh cluster from the orchard and convey by trucks, then pour the fluster into the discharge door after weighed by ground weigher . The discharge door has discharging channels, the upper and lower switches of the iron gate are controlled by pneumatic, Pneumatic control system consists of air compressor and pneumatic control devices. Start the control valve to open the gate of the discharge door, then the palm fruits will fall into the fruit basket car or conveyor.

The equipment list of the reception station:

1.Road Weighbridge

2.FFB Loading Ramp C/W Platform&Hydraulic System

3.FFB Scraper Conveyor No.1

4.FFB Incline Scraper Conveyor No.2

5.FFB Distributing Scraper Conveyor

6.Recycling FFB Conveyor

Palm bunch sterilization station

Palm bunch sterilization station utilizes high temperature (145℃, 90-120min) to cook palm bunches. Palm fruit can easily separate from palm bunches and become soft. Owing to increasing humidity of palm fruit, crude palm oil can be easily extracted from fruit. Palm kernel core can much easy separate from kernel shell, preventing enzymatic decomposition, and avoid elevated levels of free fatty acids.

Processing flow of sterilization station during palm oil processing machine:

Rail car brings raw material from reception station into the sterilization tank. Open steam system to make high temperature sterilization to kill the yeast in raw material, destroys esterase activity, then send to the next station of threshing station.

Recover condensate in sterilization tank, discharge subsequent section of the slag pit. The special silencer system design of sterilization tank vapor emission can reduce noise pollution.

The equipment list of sterilization station:

1.Vertical Steriliser c/w Hydraulic System

2.Steriliser Service Platform

3.Blow-off Silencer&Blow Down Chamber

4.Condensate Pit c/w 2 units Pump

5.Sterilizer Control System

6.SFB Incline Scraper Conveyor

7.SFB Distributing Scraper Conveyor

Palm Threshing station

Palm Threshing station uses strong vibration to make separation of palm fruit from palm bunches. Raw materials after sterilization are sent to bucket elevator through damp car, and elevated into threshing machine. Palm fruit separates from bunches, sent to next section elevator through screw conveyor. Empty bunches through conveyor and charger, are transported to certain place for further treatment by car.

Palm fruit threshing station can vibrate palm fruit from palm bunches efficiently. It makes further preparation for next step palm fruit oil press processing.

The equipment of threshing station:

1.Threshing Machine c/w Platform

2.Below Thresher Conveyor

3.Bottom Cross Conveyor

4.Horizontal Empty Bunch Conveyor

5.Inclined Empty Bunch Conveyor

Palm Oil Press Section

Because of cooking, sterilizing, threshing and mashing made the pulp soft and damage pulp cell structure, the palm pulp becomes soft and cell is broken. Then it is sent to continuous screw press. After pressing, oil palm fruit is divided into two parts: the mixture of oil, water and solid impurities, and the press cake (fiber and nut).The pulp stone separation obtained CPO and stone, press machine adopts the double screw helix continuous discharge and hydraulic, greatly improving production efficiency.

Palm Oil press station: Separate palm fruit and kernel, and oil press machine can obtain CPO (crude palm oil) and palm kernel. The adoption of double screw and hydraulic oil press machine can greatly improving working efficiency during palm oil production.

Process flow of palm oil pressing processing line:

Palm fruits through elevator and conveyors, enters into upper steaming boiler of oil press machine.

Stirring and heating with steam to destroy the emulsified state forming from oil and water, wherein the coagulation protein denaturation and to reduce the viscosity of the oil for further convenience of palm oil pressing process.

Digesting temperature keeps at 95-100℃ about 20 minutes.

Palm fruit after digesting enters into screw oil expeller for palm oil pressing.

The equipment list of pressing station:

1.Fruit Elevator

2.Digester Feed Conveyor

3.Digester Feed Conveyor

4.Fruit Recycle Conveyor

5.Digester 3000 Litter

6.Screw Press P10

7.Crude Oil Gutter

8.Sand Trap Tank

9.Vibrating Screen

10.Vibrating Screen Steel Structure Platform

11.Crude Oil Tank No.1

12.Hot Water Tank

13.Press Structure&Platform

Palm Oil Clarification station

Palm Oil Clarification station can extract crude palm oil from sludge. The obtained crude palm oil purity can reach up 90%. The extraction oil contains 45%-55% moisture, sludge and other impurities.

Purification: crude palm oil purification can improve oil purity and remove impurity successfully.

Drying: Continuous Vacuum drier pumps water from crude palm oil. Palm oil moisture can reduces to as low as 0.1%.

Continuous clarification tank clear lake containing oil enters into the oil tank, pump into centrifuge separation. The separated palm oil enters into circulating tank, and circulating pump sends it into oil clarification tank.

The separated waste oil enters into slag pit discharge, and the upper oil is recovered into circulation oil tank.

The equipment list of oil clarification station:

1.1st Stage Precleaner c/w Pump

2.Vertical Continuous Setting Tank

3.Pure Oil Tank

4.Pure Oil Pump

5.Vacuum Oil Dryer c/w Float Tank and Pump

6.Sludge Oil Tank

7.2nd Stage Precleaner c/w Pump

8.SS.Decanter Feed Tank

9.Separator Feed Tank

10.Decanter Hot Water Tank

11.3PH Decanter

12.3PH Decanter Platform

13.Decanter Reject Screw Conveyor

14.Decanter Reject Screw Conveyor

15.Light Phase Tank

16.Light Phase Pump

17.Sludge Settings&Reclaimed Oil Tank

18.oil collect tank

19.S.S Skimmer

20.Reclaimed Oil Pump

21.Hot Well Tank

22.Hot Well Pump

23.Sludge Pit Pump

24.Sludge Dispatch Pump

25.Clarification Station Platform Around Tanks

26.OIL Centrifugal

27.Sludge Separator

Palm kernel recovery station

Palm kernel recovery station assures high efficiency recovery process of palm kernel after palm oil pressing processing line. It prepares for further step palm kernel oil pressing process after splitter and crushing.

Depericarper (splitter). Palm kernel separates from fibers through floating dry processing during crude palm oil processing machine. Fibers and other light stuff are blown appearance.

Crushing. The crusher breaks palm kernel to separate kernel and shell. The hydrocyclone separates palm kernel from shell particles by using of their proportion.

Effluent Treatment Station

The waste water has high organic matter content, biochemical oxygen demand BOD is about 25000ppm, required by qualified deal before emissions. Pool sewage treatment system is the most used and effective treatment. This treatment system is cost-effective, only needs adequate space, less investment costs.

The equipment list of effluent treatment station:

1.Effluent Treatment Pump

2.Effluent Dispatch Pump

3.Surface Aerators

4.Effluent Piping Works

Palm oil is extracted from fresh fruit bunches (FFB) by a mechanical process, where a mill commonly handles 2.5 to 150 MT per hour of FFB.

The quality of crude palm oil depends on the care taken after harvesting, particularly in the handling of the FFBs and the process adopted.

A palm oil mill produces crude palm oil and kernels as primary products and biomass as secondary product. The capacity of mills varies between 2.5 - 150 MT FFB/hr. A typical mill has many operational units as shown in Figure 2. This comprises of sterilization, stripping, digestion and pressing, clarification, purification, drying and storage. For the kernel line, there are steps such as nut/fiber separation, nut conditioning and cracking, cracked mixture separation, and kernel drying and storage. The dried kernels are often sold to palm kernel crushers for extraction of crude palm kernel oil. In some integrated plants, kernel crushing facilities exist side by side in the same complex.

Palm Oil Mill Processing Line

Palm bunch reception is the primary processing of crude palm oil processing machine. It makes preparation for raw material processing and treatment.Palm bunch reception process is finished at loading ramp. This loading ramp makes palm fruit unloading, cleaning, storage platforms, adopting all hydraulic segmented discharge.Palm bunch reception section make primary preparation of crude palm oil pressing, and enable processing of palm bunch efficiently.

Collecting the ripe fresh cluster from the orchard and convey by trucks, then pour the fluster into the discharge door after weighed by ground weigher . The discharge door has discharging channels, the upper and lower switches of the iron gate are controlled by pneumatic, Pneumatic control system consists of air compressor and pneumatic control devices. Start the control valve to open the gate of the discharge door, then the palm fruits will fall into the fruit basket car or conveyor.

The equipment list of the reception station:

1.Road Weighbridge

2.FFB Loading Ramp C/W Platform&Hydraulic System

3.FFB Scraper Conveyor No.1

4.FFB Incline Scraper Conveyor No.2

5.FFB Distributing Scraper Conveyor

6.Recycling FFB Conveyor

Palm bunch sterilization station

Palm bunch sterilization station utilizes high temperature (145℃, 90-120min) to cook palm bunches. Palm fruit can easily separate from palm bunches and become soft. Owing to increasing humidity of palm fruit, crude palm oil can be easily extracted from fruit. Palm kernel core can much easy separate from kernel shell, preventing enzymatic decomposition, and avoid elevated levels of free fatty acids.

Processing flow of sterilization station during palm oil processing machine:

Rail car brings raw material from reception station into the sterilization tank. Open steam system to make high temperature sterilization to kill the yeast in raw material, destroys esterase activity, then send to the next station of threshing station.

Recover condensate in sterilization tank, discharge subsequent section of the slag pit. The special silencer system design of sterilization tank vapor emission can reduce noise pollution.

The equipment list of sterilization station:

1.Vertical Steriliser c/w Hydraulic System

2.Steriliser Service Platform

3.Blow-off Silencer&Blow Down Chamber

4.Condensate Pit c/w 2 units Pump

5.Sterilizer Control System

6.SFB Incline Scraper Conveyor

7.SFB Distributing Scraper Conveyor

Palm Threshing station

Palm Threshing station uses strong vibration to make separation of palm fruit from palm bunches. Raw materials after sterilization are sent to bucket elevator through damp car, and elevated into threshing machine. Palm fruit separates from bunches, sent to next section elevator through screw conveyor. Empty bunches through conveyor and charger, are transported to certain place for further treatment by car.

Palm fruit threshing station can vibrate palm fruit from palm bunches efficiently. It makes further preparation for next step palm fruit oil press processing.

The equipment of threshing station:

1.Threshing Machine c/w Platform

2.Below Thresher Conveyor

3.Bottom Cross Conveyor

4.Horizontal Empty Bunch Conveyor

5.Inclined Empty Bunch Conveyor

Palm Oil Press Section

Because of cooking, sterilizing, threshing and mashing made the pulp soft and damage pulp cell structure, the palm pulp becomes soft and cell is broken. Then it is sent to continuous screw press. After pressing, oil palm fruit is divided into two parts: the mixture of oil, water and solid impurities, and the press cake (fiber and nut).The pulp stone separation obtained CPO and stone, press machine adopts the double screw helix continuous discharge and hydraulic, greatly improving production efficiency.

Palm Oil press station: Separate palm fruit and kernel, and oil press machine can obtain CPO (crude palm oil) and palm kernel. The adoption of double screw and hydraulic oil press machine can greatly improving working efficiency during palm oil production.

Process flow of palm oil pressing processing line:

Palm fruits through elevator and conveyors, enters into upper steaming boiler of oil press machine.

Stirring and heating with steam to destroy the emulsified state forming from oil and water, wherein the coagulation protein denaturation and to reduce the viscosity of the oil for further convenience of palm oil pressing process.

Digesting temperature keeps at 95-100℃ about 20 minutes.

Palm fruit after digesting enters into screw oil expeller for palm oil pressing.

The equipment list of pressing station:

1.Fruit Elevator

2.Digester Feed Conveyor

3.Digester Feed Conveyor

4.Fruit Recycle Conveyor

5.Digester 3000 Litter

6.Screw Press P10

7.Crude Oil Gutter

8.Sand Trap Tank

9.Vibrating Screen

10.Vibrating Screen Steel Structure Platform

11.Crude Oil Tank No.1

12.Hot Water Tank

13.Press Structure&Platform

Palm Oil Clarification station

Palm Oil Clarification station can extract crude palm oil from sludge. The obtained crude palm oil purity can reach up 90%. The extraction oil contains 45%-55% moisture, sludge and other impurities.

Purification: crude palm oil purification can improve oil purity and remove impurity successfully.

Drying: Continuous Vacuum drier pumps water from crude palm oil. Palm oil moisture can reduces to as low as 0.1%.

Continuous clarification tank clear lake containing oil enters into the oil tank, pump into centrifuge separation. The separated palm oil enters into circulating tank, and circulating pump sends it into oil clarification tank.

The separated waste oil enters into slag pit discharge, and the upper oil is recovered into circulation oil tank.

The equipment list of oil clarification station:

1.1st Stage Precleaner c/w Pump

2.Vertical Continuous Setting Tank

3.Pure Oil Tank

4.Pure Oil Pump

5.Vacuum Oil Dryer c/w Float Tank and Pump

6.Sludge Oil Tank

7.2nd Stage Precleaner c/w Pump

8.SS.Decanter Feed Tank

9.Separator Feed Tank

10.Decanter Hot Water Tank

11.3PH Decanter

12.3PH Decanter Platform

13.Decanter Reject Screw Conveyor

14.Decanter Reject Screw Conveyor

15.Light Phase Tank

16.Light Phase Pump

17.Sludge Settings&Reclaimed Oil Tank

18.oil collect tank

19.S.S Skimmer

20.Reclaimed Oil Pump

21.Hot Well Tank

22.Hot Well Pump

23.Sludge Pit Pump

24.Sludge Dispatch Pump

25.Clarification Station Platform Around Tanks

26.OIL Centrifugal

27.Sludge Separator

Palm kernel recovery station

Palm kernel recovery station assures high efficiency recovery process of palm kernel after palm oil pressing processing line. It prepares for further step palm kernel oil pressing process after splitter and crushing.

Depericarper (splitter). Palm kernel separates from fibers through floating dry processing during crude palm oil processing machine. Fibers and other light stuff are blown appearance.

Crushing. The crusher breaks palm kernel to separate kernel and shell. The hydrocyclone separates palm kernel from shell particles by using of their proportion.

Effluent Treatment Station

The waste water has high organic matter content, biochemical oxygen demand BOD is about 25000ppm, required by qualified deal before emissions. Pool sewage treatment system is the most used and effective treatment. This treatment system is cost-effective, only needs adequate space, less investment costs.

The equipment list of effluent treatment station:

1.Effluent Treatment Pump

2.Effluent Dispatch Pump

3.Surface Aerators

4.Effluent Piping Works

Technical parameters

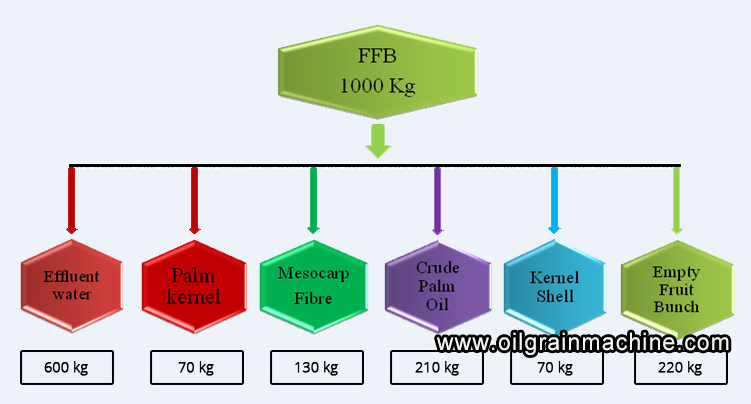

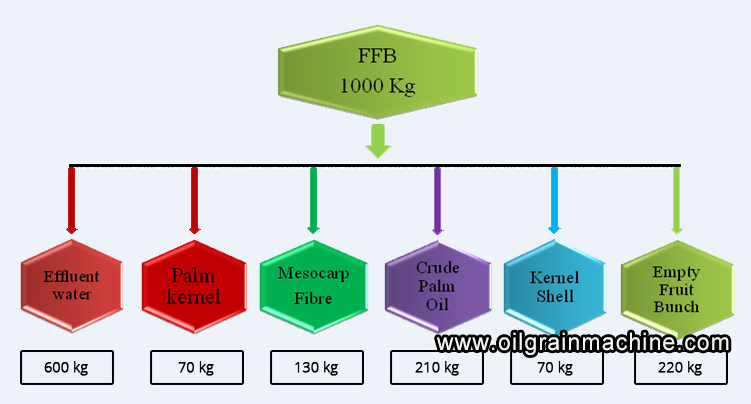

Palm Fruit Balance

Palm Oil Mill Processing Line

Palm Oil Mill Processing Line

FAQ

Our Sinoder Indutech Machine supply the complete set of Cooking oil production line machinery including sunflower oil production line, palm oil production line, soya bean oil production line, peanut oil production line, cotton seeds oil production line, maize corn germ oil production line, clamelia oil production line, rapeseeds oil production line, canola oil production line, coconut cropra oil production line, shea oil production line, groundnuts oil line, sesame oil production line,black seeds oil production line, jatropha seeds oil production line,moringa seeds oil production line

Q1 : Which kind of materials can be processed?

All kinds of oil seeds. For example, sunflower seeds, rice bran, corn germ, palm fruit, palm kernel,coconut,peanut, soybean, sesame, cottonseeds, rapeseed, etc.

Q2 : What's the capacity?

Generally, 10-5000 tons per day. We can also manufacture as per customers' requirements.

Q3 : How long is the warranty?

The main parts of the machine come with one year warranty and after the expiration our engineer is available overseas to do the maintenance work.

Q4 : Can the machine be installed locally?

We can do the turn-key projects or other services according to customers'requirements,according to this condition,our services can be manufacturing,purchasing,transporting,installation,training labors etc.

Q5 : How to operate the machine?

Our engineers will be available to guide and train your labors how to operate and run the machine.

Q1 : Which kind of materials can be processed?

All kinds of oil seeds. For example, sunflower seeds, rice bran, corn germ, palm fruit, palm kernel,coconut,peanut, soybean, sesame, cottonseeds, rapeseed, etc.

Q2 : What's the capacity?

Generally, 10-5000 tons per day. We can also manufacture as per customers' requirements.

Q3 : How long is the warranty?

The main parts of the machine come with one year warranty and after the expiration our engineer is available overseas to do the maintenance work.

Q4 : Can the machine be installed locally?

We can do the turn-key projects or other services according to customers'requirements,according to this condition,our services can be manufacturing,purchasing,transporting,installation,training labors etc.

Q5 : How to operate the machine?

Our engineers will be available to guide and train your labors how to operate and run the machine.