Key Machines

Latest News

Cooking Oil Production Line

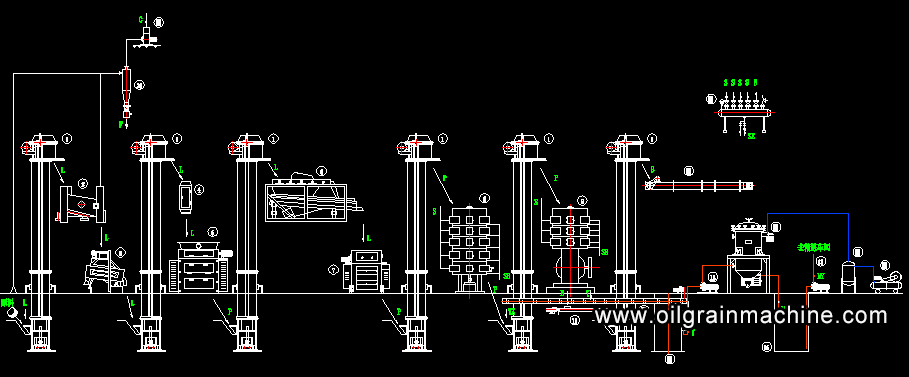

Sunflower Seeds Oil Press Line Machinery

Processes of sunflower seeds pretreatment and prepressing workshop

Oil seeds -- Magnetic box-- Cleaning Sieve-- Crusher -- Flaking roll -- Cooker -- Oil prepressing --

Cakes -- Solvent Extraction workshop

Crude oil -- Refining workshop

The whole process of the sunflower oil processing line machine can be divided into three workshop : the pretreatment processing workshop , the solvent extraction processing workshop , and the oil refinery processing workshop.

Oil seeds -- Magnetic box-- Cleaning Sieve-- Crusher -- Flaking roll -- Cooker -- Oil prepressing --

Cakes -- Solvent Extraction workshop

Crude oil -- Refining workshop

The whole process of the sunflower oil processing line machine can be divided into three workshop : the pretreatment processing workshop , the solvent extraction processing workshop , and the oil refinery processing workshop.

We're here to help: Easy ways to get the answers you need.

Product Introduction

Sunflower seeds are composed of peel (shell) and seed, the seed consists of seed coat, two pieces of cotyledon and embryo. Peel three layers, pericarp membranous, with short hairs;Mesocarp leathery, hard and thick;Endocarp villous. Kind of leather for two pieces of cotyledon hypertrophy, and radicle, embryonic stem, germ, without endosperm.Radicle and embryo stem, germ is located in the tip of the seeds.Kind of skin consists of two layers, outer skin and inner, with a white film.

Processes of sunflower seeds pretreatment and prepressing workshop

Oil seeds -- Magnetic box-- Cleaning Sieve-- Crusher -- Flaking roll -- Cooker -- Oil prepressing --

Cakes -- Solvent Extraction workshop

Crude oil -- Refining workshop

The whole process of the sunflower oil processing line machine can be divided into three workshop : the pretreatment processing workshop , the solvent extraction processing workshop , and the oil refinery processing workshop.

Pretreatment and prepressing section is a very important section before extraction. It will directly affect extraction effect.

The set of pretreatment and prepressing equipment of sunflower seeds oil press line includes cleaning, dehulling, separating, drying, crushing, softening, germ pressing, steaming, roasting and prepressing sections and so on.

1. Cleaning of sunflower seed oil production line,sunflower seed oil making machine

1).According to different particle size between oilseeds and impurities,remove big and small impurities from oilseeds with vibrating screen.

2). Stones removal. According to different specific gravity and suspended velocity between oilseeds and stones, stones fall down and oilseeds suspend under the action of air flow to separate stones from oilseeds.

3). Magnetic selection. It uses magnet to remove metal impurities from oilseeds. Strong and uniform magnetism attract metals automaically and remove metals to prevent oilseeds carrying stones away, attracted metals by permanent magnet fall down automatically when metals reach non-magnetic area.

4). Screening Section. Remove impurities whose size is similiar to oilseeds according to different mechanical performance between oilseeds and clods, crush clods and then separate them through screen selection or wind selection.

2. Husking - sunflower seed oil production line,sunflower seed oil making machine

Adopt wind selection and screen selection methods to separate husks from kernels.

3. Crushing of sunflower seed oil production line,sunflower seed oil making machine

Before flaking, crush big oilseeds into smaller pieces to increase superficial area, beneficial for transfering softening temperature and moisture, improve softening efficiency.

4. Softening of sunflower seed oil production line,sunflower seed oil making machine

Adjust moisture and temperature of oilseeds to improve their plastivity and reach required flaking condition.

5. Flaking of sunflower seed oil production line,sunflower seed oil making machine

Roll oilseeds from pellets to thin flakes through mechanical method.

6.Cooking of sunflower seed oil production line,sunflower seed oil making machine

Steam and cook green-pressing to cooked flakes through moist, heating, steaming and cooking to break the cellular structure so as to improve pressing oil yield and improve quality of oil and cake or meal.

7.Pre-pressing of sunflower seed oil production line,sunflower seed oil making machine

For oilseeds with high oil content, it needs pre-pressing to press part of oil firstly and then extract residual oil in cake through solvent extraction method.

Raw materials of oil pretreatment equipment involved: soybean, peanut, rapeseed, cottonseed, sunflower seeds, palm nuts, linseed, tea seed, corn embryo, rice bran, oil seeds, etc.

Technical parameters

Sunflower Seeds and other oilseeds oil expeller production line:

| Power consumption | 36KWH / t |

| Steam consumption | 280 kg / t |

| Pre-pressed cake thicknes | ≤17mm |

| Pre-pressed cake moisture | ≤4-6% |

| Pre-pressed Residual oil | ≤14-16% |

FAQ

What kinds of materials can be processed?

Press production line: peanut, sunflower seed, corn germ, cotton seed, soybean, rapeseeds, sesame , rice bran etc.

Solvent extraction line: soybean, sunflower and various pressed oil cakes, waste white clay etc.

Refinery production line: palm oil, peanut oil, sunflower oil, soybean oil and various kinds crude vegetable oil.

Biodiesel production line: Used cooking oil , various kinds vegetable oil and animal oil.

what we supply:

Cooking oil production line machinery including sunflower oil production line, palm oil production line, soya bean oil production line, peanut oil production line, cotton seeds oil production line, maize corn germ oil production line, clamelia oil production line, rapeseeds oil production line, canola oil production line, coconut cropra oil production line, shea oil production line, groundnuts oil line, sesame oil production line,black seeds oil production line, jatropha seeds oil production line,moringa seeds oil production line machinery and other projects.

Professional advice

If you are interest in our machines, please tell me your raw materials , daily capacity, requirements of final products, so that we can accord to your demand to amke a professional proposal.

If your are the new investor of this field, please let us know your whole plan and ideas , then we can accord to your basica demand to suggest you proper capacity and processing crafts.

Press production line: peanut, sunflower seed, corn germ, cotton seed, soybean, rapeseeds, sesame , rice bran etc.

Solvent extraction line: soybean, sunflower and various pressed oil cakes, waste white clay etc.

Refinery production line: palm oil, peanut oil, sunflower oil, soybean oil and various kinds crude vegetable oil.

Biodiesel production line: Used cooking oil , various kinds vegetable oil and animal oil.

what we supply:

Cooking oil production line machinery including sunflower oil production line, palm oil production line, soya bean oil production line, peanut oil production line, cotton seeds oil production line, maize corn germ oil production line, clamelia oil production line, rapeseeds oil production line, canola oil production line, coconut cropra oil production line, shea oil production line, groundnuts oil line, sesame oil production line,black seeds oil production line, jatropha seeds oil production line,moringa seeds oil production line machinery and other projects.

Professional advice

If you are interest in our machines, please tell me your raw materials , daily capacity, requirements of final products, so that we can accord to your demand to amke a professional proposal.

If your are the new investor of this field, please let us know your whole plan and ideas , then we can accord to your basica demand to suggest you proper capacity and processing crafts.

Prev:第一页