Key Machines

Latest News

Cooking Oil Production Line

Maize Corn Germ Oil Production Line Machinery

Maize germ/ Corn germ oil is extracted from corn germ, which is one of the most commonly used cooking oil. Nowadays a complete corn germ oil production line consists of prepressing workshop, extraction workshop and refining workshop.

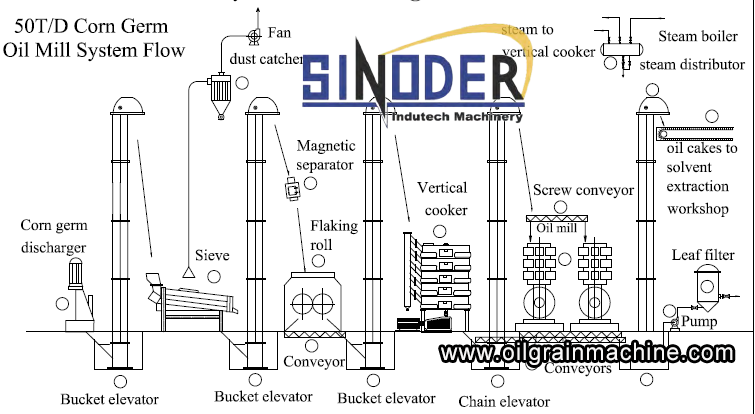

In prepressing workshop, impurities entrained in corn germ being cleared. Then corn germs are processed into flakes with appropriate temperature and moisture through a sequence of treatment. The flakes go for pressing directly. Prepressing workshop usually includes cleaning, softening, flaking, steaming&cooking, pressing and other sections.

In prepressing workshop, impurities entrained in corn germ being cleared. Then corn germs are processed into flakes with appropriate temperature and moisture through a sequence of treatment. The flakes go for pressing directly. Prepressing workshop usually includes cleaning, softening, flaking, steaming&cooking, pressing and other sections.

We're here to help: Easy ways to get the answers you need.

Product Introduction

Maize Germ/ Corn germ Oil Production Line Plant

Maize germ/ Corn germ oil is extracted from corn germ, which is one of the most commonly used cooking oil. Nowadays a complete corn germ oil production line consists of prepressing workshop, extraction workshop and refining workshop.

In prepressing workshop, impurities entrained in corn germ being cleared. Then corn germs are processed into flakes with appropriate temperature and moisture through a sequence of treatment. The flakes go for pressing directly. Prepressing workshop usually includes cleaning, softening, flaking, steaming&cooking, pressing and other sections.

In prepressing workshop, impurities entrained in corn germ being cleared. Then corn germs are processed into flakes with appropriate temperature and moisture through a sequence of treatment. The flakes go for pressing directly. Prepressing workshop usually includes cleaning, softening, flaking, steaming&cooking, pressing and other sections.

Commercialized Maize / Corn Germ Oil Expeller System

Maize germ/ Corn germ oil is extracted from corn germ, which is one of the most commonly used cooking oil. Nowadays a complete corn germ oil production line consists of prepressing workshop, extraction workshop and refining workshop.

In prepressing workshop, impurities entrained in corn germ being cleared. Then corn germs are processed into flakes with appropriate temperature and moisture through a sequence of treatment. The flakes go for pressing directly. Prepressing workshop usually includes cleaning, softening, flaking, steaming&cooking, pressing and other sections.

In prepressing workshop, impurities entrained in corn germ being cleared. Then corn germs are processed into flakes with appropriate temperature and moisture through a sequence of treatment. The flakes go for pressing directly. Prepressing workshop usually includes cleaning, softening, flaking, steaming&cooking, pressing and other sections.

Commercialized Maize / Corn Germ Oil Expeller System

Technical parameters

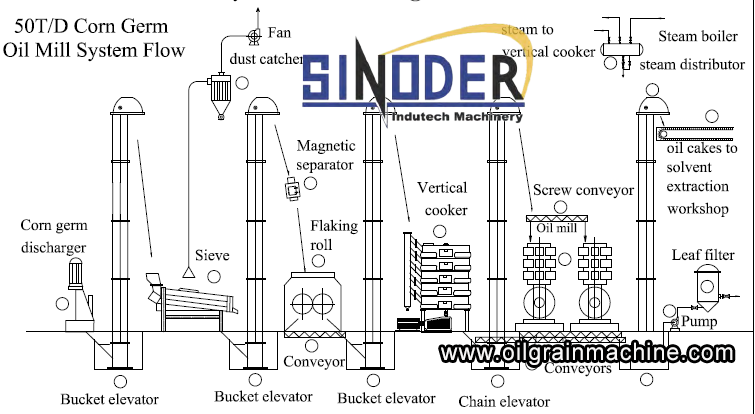

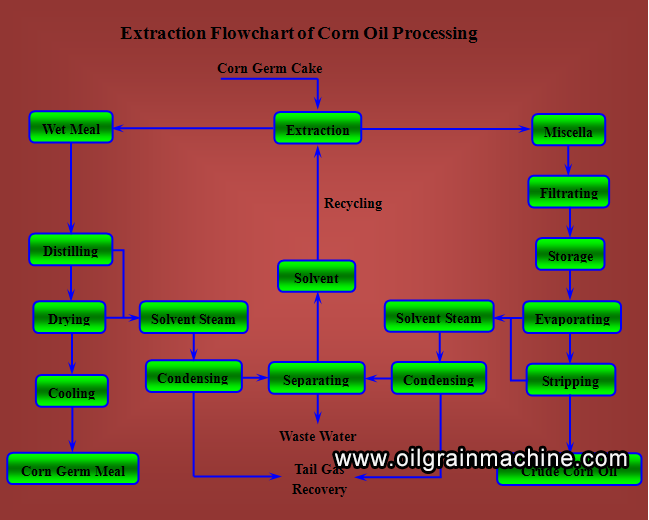

In extraction workshop, the corn germ cake from prepressing workshop are soaked and sprayed by a special solvent. In this way, oil is extracted. After a series of separation, distillation and desolvation, we get crude corn germ oil and corn germ meal. Extraction usually includes solvent extraction, desolventizing of wet meal, evaporating and stripping of miscella, solvent steam condensation and recovery, vent gas recovery and other sections.

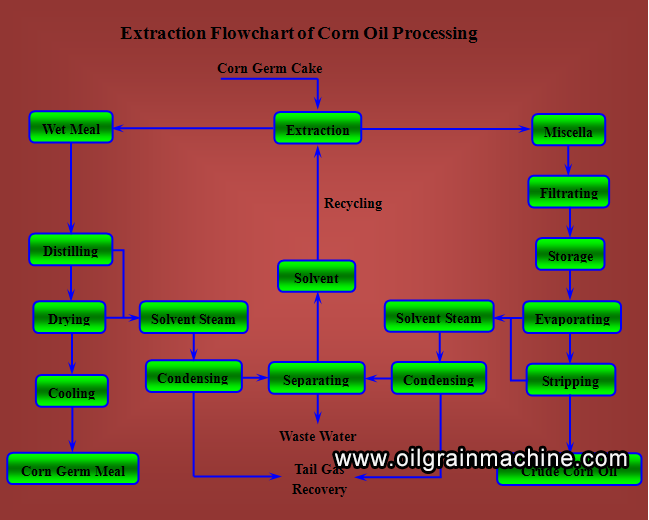

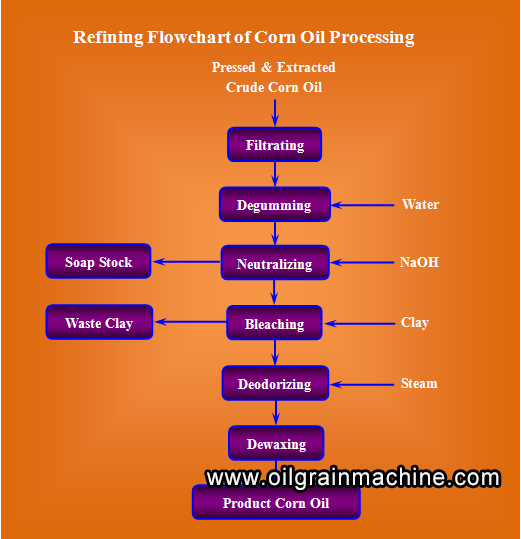

In refining workshop, the pressed crude corn oil and the extracted crude corn oil become product corn oil by special processing to get rid of impurities, gums, FFA, pigment and odors. Refinery usually includes degumming, neutralizing, bleaching, deodorizing, dewaxing and other sections.

Sinoder Corporation Business Scope

Content of engineering: process design, general contract engineering for mechanical & electrical equipment construction and installation & debugging.

1. 10-5000T/D Oilseed preliminary cleaning, drying, storage section turn-key project

2. 5-5000T/D Oilseed pretreatment & pre-pressing production line turn-key project

3. 100-5000T/D Oilseed extraction production line turn-key project

4. 5-3000T/D Physical (Chemical) refining, fractionation production line turn-key project

5. 10-3000T/D Cold pressed peanut synchronization extraction protein powder under low temperature turn-key project

6. 10-1000T/D Phospholipid concentrate production line turn-key project

7. 10-500T/D Animal oil boil, refining, shortening and margarine turn-key project

8. 10-500T/D Biodiesel production line turn-key project

9. 10-1500T/D Cottonseed husking project

10. 10-3000T/D Sunflower oil, rice bran oil, corn germ oil pressing, refining, dewaxing turn-key project

11. 1-100T/D Peony seed oil, tea seed oil, ect. turn-key project

12. 10-2000T/D Full automatic control filling packing production line turn-key project.

In refining workshop, the pressed crude corn oil and the extracted crude corn oil become product corn oil by special processing to get rid of impurities, gums, FFA, pigment and odors. Refinery usually includes degumming, neutralizing, bleaching, deodorizing, dewaxing and other sections.

Sinoder Corporation Business Scope

Content of engineering: process design, general contract engineering for mechanical & electrical equipment construction and installation & debugging.

1. 10-5000T/D Oilseed preliminary cleaning, drying, storage section turn-key project

2. 5-5000T/D Oilseed pretreatment & pre-pressing production line turn-key project

3. 100-5000T/D Oilseed extraction production line turn-key project

4. 5-3000T/D Physical (Chemical) refining, fractionation production line turn-key project

5. 10-3000T/D Cold pressed peanut synchronization extraction protein powder under low temperature turn-key project

6. 10-1000T/D Phospholipid concentrate production line turn-key project

7. 10-500T/D Animal oil boil, refining, shortening and margarine turn-key project

8. 10-500T/D Biodiesel production line turn-key project

9. 10-1500T/D Cottonseed husking project

10. 10-3000T/D Sunflower oil, rice bran oil, corn germ oil pressing, refining, dewaxing turn-key project

11. 1-100T/D Peony seed oil, tea seed oil, ect. turn-key project

12. 10-2000T/D Full automatic control filling packing production line turn-key project.

FAQ

Our Sinoder Indutech Machine supply the complete set of Cooking oil production line machinery including sunflower oil production line, palm oil production line, soya bean oil production line, peanut oil production line, cotton seeds oil production line, maize corn germ oil production line, clamelia oil production line, rapeseeds oil production line, canola oil production line, coconut cropra oil production line, shea oil production line, groundnuts oil line, sesame oil production line,black seeds oil production line, jatropha seeds oil production line,moringa seeds oil production line

Q1 : Which kind of materials can be processed?

All kinds of oil seeds. For example, sunflower seeds, rice bran, corn germ, palm fruit, palm kernel,coconut,peanut, soybean, sesame, cottonseeds, rapeseed, etc.

Q2 : What's the capacity?

Generally, 10-5000 tons per day. We can also manufacture as per customers' requirements.

Q3 : How long is the warranty?

The main parts of the machine come with one year warranty and after the expiration our engineer is available overseas to do the maintenance work.

Q4 : Can the machine be installed locally?

We can do the turn-key projects or other services according to customers'requirements,according to this condition,our services can be manufacturing,purchasing,transporting,installation,training labors etc.

Q5 : How to operate the machine?

Our engineers will be available to guide and train your labors how to operate and run the machine.

Q1 : Which kind of materials can be processed?

All kinds of oil seeds. For example, sunflower seeds, rice bran, corn germ, palm fruit, palm kernel,coconut,peanut, soybean, sesame, cottonseeds, rapeseed, etc.

Q2 : What's the capacity?

Generally, 10-5000 tons per day. We can also manufacture as per customers' requirements.

Q3 : How long is the warranty?

The main parts of the machine come with one year warranty and after the expiration our engineer is available overseas to do the maintenance work.

Q4 : Can the machine be installed locally?

We can do the turn-key projects or other services according to customers'requirements,according to this condition,our services can be manufacturing,purchasing,transporting,installation,training labors etc.

Q5 : How to operate the machine?

Our engineers will be available to guide and train your labors how to operate and run the machine.