Key Machines

Latest News

Oil Refinery Plant

Vegetable Oil Refining Machines – Solution and Technology

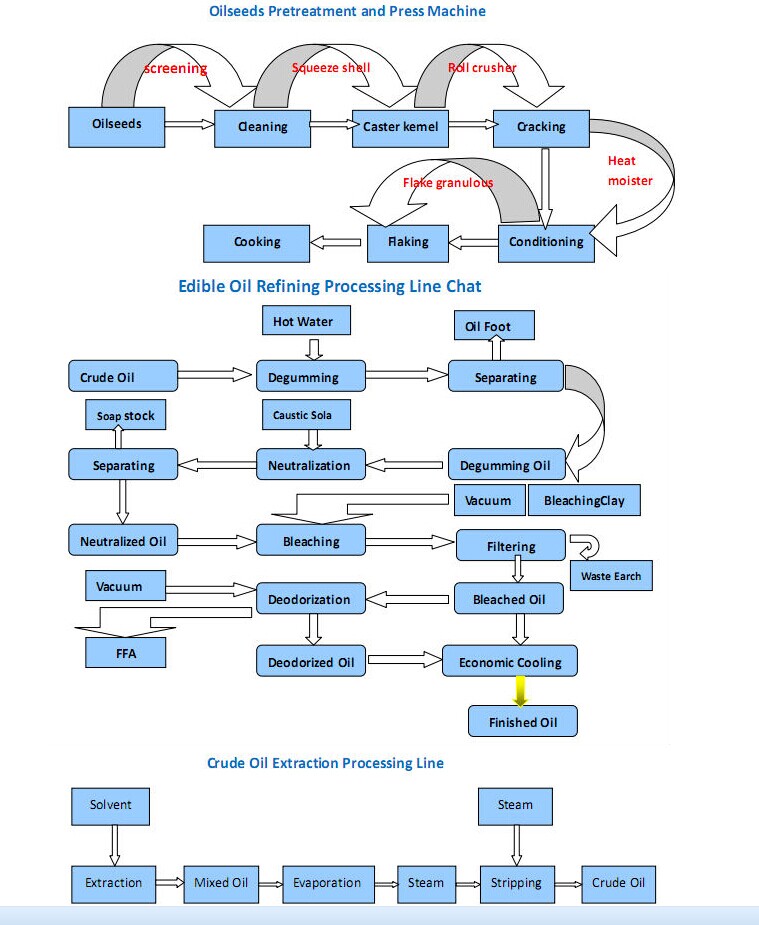

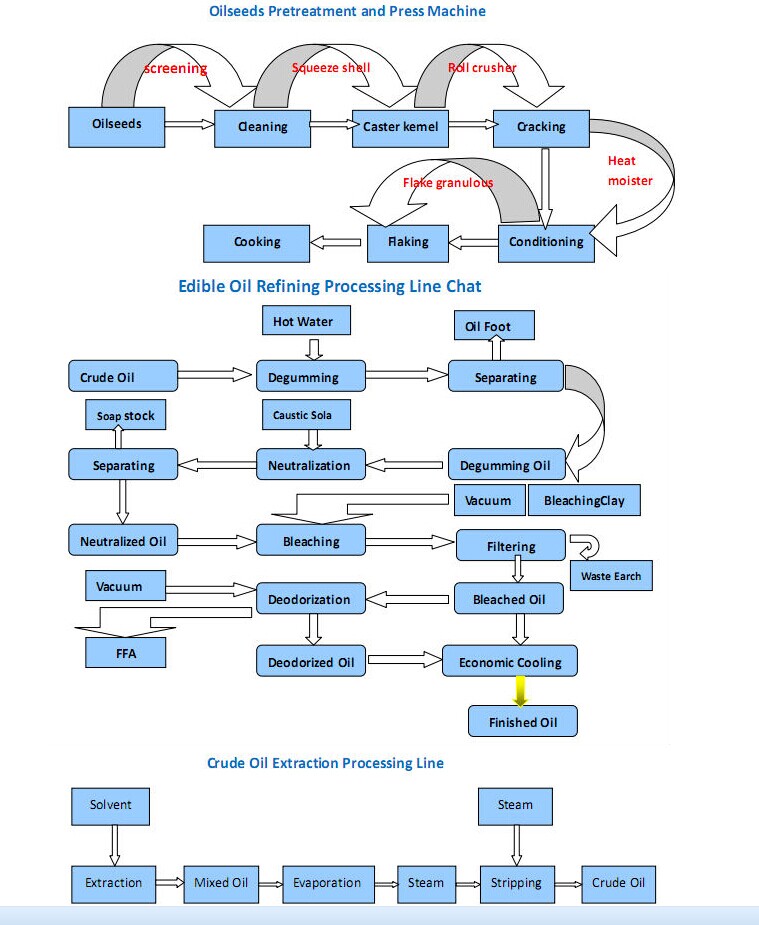

Edible oil refining contains vegetable oil refining, animal oil refining, microbial oil refining. The crude oil refining production line can remove impurity of oil and obtain high quality standard finished refined oil through washed degumming, alkali refining soap removal, mixed proportion, blenching, filtration, physical deacidification and deodorization, crystallization and maturing.

Refining is carried out either on batch operation or as continuous operation. With certain oils even physical refining can be carried out instead of chemical.

We're here to help: Easy ways to get the answers you need.

Product Introduction

Vegetable Oil Refining Machines – Solution and Technology

Edible oil refining contains vegetable oil refining, animal oil refining, microbial oil refining. The crude oil refining production line can remove impurity of oil and obtain high quality standard finished refined oil through washed degumming, alkali refining soap removal, mixed proportion, blenching, filtration, physical deacidification and deodorization, crystallization and maturing.

Refining is carried out either on batch operation or as continuous operation. With certain oils even physical refining can be carried out instead of chemical.

Batch Refining Plant

Refining of vegetable oils is essential to ensure removal of gums, waxes, phosphatides and free fatty acid (F. F.A.) from the oil; to impart uniform colour by removal of colouring pigments and to get rid of unpleasant smell from the oil by removal of odiferous matter.

The equipment involved are Neutralizer, Bleacher, Deodorizer, Heat Exchanger, High & low vacuum equipment & Filters.

Continuous Refining Line Plant

Refining of vegetable oils is essential to ensure removal of Gums, Waxes, Phosphatides and Free Fatty Acids (F.F.A.) from the oils.

Continuous Refining will comprise of following steps:-

Pretreatment / Degumming Section:-

Here the oils are given acidic treatment where by gums are precipitated and separated out by centrifugal separation or some times only gum conditioning is carried out (when gum content is low) and gums are separated in subsequent neutralising process.

Neutralising Section:-

The pretreated oil is subjected to Alkali Refining. The caustic soda reacts with Free Fatty Acids (F.F.A.) present in the oil and forms soap stock, the soap stock is separated out by centrifugal separator, oil is washed with water for complete removal of soap stock. The wash water is separated out by centrifugal separators.

Bleaching Section:-

The neutralized oil is treated with bleaching earth/activated carbon for removal of colouring pigments. The bleaching agent is filtered out in vertical pressure leaf filters. Sinoder design ensures uniform consistency in colour with minimum requirement of bleaching agent. The bleaching line is versatile and adoptable for all varieties of vegetable oils.

Deodorization Process:-

As the name suggest process is meant for removal of odour. Every vegetable oil has its own distinct natural odour. During neutralization and bleaching operation unpleasant odour is imparted to the oil, it is therefore essential to remove this odour. The deodorisation is essentially a process of removal of odiferous matter. The operation is carried out at high temperature by injecting open steam and maintaining high vacuum at which time all odoriferous matter is distilled off and carried away to barometric condensors through vacuum system. The resultant oil is odourless – deodorized oil.

Dewaxing Section :-

Oils like sunflower oil or maize germ oil (corn oil) have waxes present in them. At low temperature these waxes gives hazy appearance to oil, which is not liked by consumers. It is therefore essential to remove these waxes prior to bottling and marketing of oil. Sinoder offers dewaxing units.

Dry Fractionation

The widespread use of the three oil modification processes - hydrogenation, interesterification and fractionation - extended the range of applications of the triglyceride oils. These processes principally serve the purpose of modifying the melting properties of oils and fats in order to improve their functional properties in specific applications, but the processes are also used to improve the stability of the oils and fats thus processed.

In edible oil processing, a fractionation process consists of a controlled cooling of the oil, thereby inducing a partial, or ‘fractional’, crystallization. The remaining liquid (olein) is then separated from the solid fraction (stearin) by means of filtration or centrifugation.

Natural oils and fats have different characteristics due to the fact that they are composed of a great number of different triglycerides. These contain fatty acids with carbon chins of different lengths and with different degrees of unsaturation.

Triglycerides with a high degree of unsaturation, indicated by a high iodine value, have a lower melting point than those containing more saturated fatty acids. If oil is cooled to a certain temperature, the high melting triglyceride (Stearin) will crystallize while the low melting ones will remain fluid. The stearin can then be separated from oil (Olein) by different methods and the fat/oil is thus divided into two fractions: Stearin with a high melting point and olein with a low cloud and melting points.

This technique is called fractional crystallization and used to obtain oils or fats more suitable for example, as cooking oils or for margarine/shortening production.

Oil refining plant, vegetable oil refining plant, vegetable oil refining plant manufacturers, oil refining plant manufacturer,Oil Refinery Machines

Our products include vegetable seeds oil mill, soya bean oil extraction machine, palm oil refining machine, sunflower oil making machine, cooking oil machine, edible oil refineries, corn germ oil processing plant, cotton seeds oil refinery plant.

Welcome to contact us any time!

http://www.oilgrainmachine.com

http://www.sinoder.com

Video of Vegetable Seeds Oil Press and Refining Plant:

https://www.youtube.com/watch?v=0ZgkOjcZ26I

Edible oil refining contains vegetable oil refining, animal oil refining, microbial oil refining. The crude oil refining production line can remove impurity of oil and obtain high quality standard finished refined oil through washed degumming, alkali refining soap removal, mixed proportion, blenching, filtration, physical deacidification and deodorization, crystallization and maturing.

Refining is carried out either on batch operation or as continuous operation. With certain oils even physical refining can be carried out instead of chemical.

Batch Refining Plant

Refining of vegetable oils is essential to ensure removal of gums, waxes, phosphatides and free fatty acid (F. F.A.) from the oil; to impart uniform colour by removal of colouring pigments and to get rid of unpleasant smell from the oil by removal of odiferous matter.

The equipment involved are Neutralizer, Bleacher, Deodorizer, Heat Exchanger, High & low vacuum equipment & Filters.

Continuous Refining Line Plant

Refining of vegetable oils is essential to ensure removal of Gums, Waxes, Phosphatides and Free Fatty Acids (F.F.A.) from the oils.

Continuous Refining will comprise of following steps:-

Pretreatment / Degumming Section:-

Here the oils are given acidic treatment where by gums are precipitated and separated out by centrifugal separation or some times only gum conditioning is carried out (when gum content is low) and gums are separated in subsequent neutralising process.

Neutralising Section:-

The pretreated oil is subjected to Alkali Refining. The caustic soda reacts with Free Fatty Acids (F.F.A.) present in the oil and forms soap stock, the soap stock is separated out by centrifugal separator, oil is washed with water for complete removal of soap stock. The wash water is separated out by centrifugal separators.

Bleaching Section:-

The neutralized oil is treated with bleaching earth/activated carbon for removal of colouring pigments. The bleaching agent is filtered out in vertical pressure leaf filters. Sinoder design ensures uniform consistency in colour with minimum requirement of bleaching agent. The bleaching line is versatile and adoptable for all varieties of vegetable oils.

Deodorization Process:-

As the name suggest process is meant for removal of odour. Every vegetable oil has its own distinct natural odour. During neutralization and bleaching operation unpleasant odour is imparted to the oil, it is therefore essential to remove this odour. The deodorisation is essentially a process of removal of odiferous matter. The operation is carried out at high temperature by injecting open steam and maintaining high vacuum at which time all odoriferous matter is distilled off and carried away to barometric condensors through vacuum system. The resultant oil is odourless – deodorized oil.

Dewaxing Section :-

Oils like sunflower oil or maize germ oil (corn oil) have waxes present in them. At low temperature these waxes gives hazy appearance to oil, which is not liked by consumers. It is therefore essential to remove these waxes prior to bottling and marketing of oil. Sinoder offers dewaxing units.

Dry Fractionation

The widespread use of the three oil modification processes - hydrogenation, interesterification and fractionation - extended the range of applications of the triglyceride oils. These processes principally serve the purpose of modifying the melting properties of oils and fats in order to improve their functional properties in specific applications, but the processes are also used to improve the stability of the oils and fats thus processed.

In edible oil processing, a fractionation process consists of a controlled cooling of the oil, thereby inducing a partial, or ‘fractional’, crystallization. The remaining liquid (olein) is then separated from the solid fraction (stearin) by means of filtration or centrifugation.

Natural oils and fats have different characteristics due to the fact that they are composed of a great number of different triglycerides. These contain fatty acids with carbon chins of different lengths and with different degrees of unsaturation.

Triglycerides with a high degree of unsaturation, indicated by a high iodine value, have a lower melting point than those containing more saturated fatty acids. If oil is cooled to a certain temperature, the high melting triglyceride (Stearin) will crystallize while the low melting ones will remain fluid. The stearin can then be separated from oil (Olein) by different methods and the fat/oil is thus divided into two fractions: Stearin with a high melting point and olein with a low cloud and melting points.

This technique is called fractional crystallization and used to obtain oils or fats more suitable for example, as cooking oils or for margarine/shortening production.

Oil refining plant, vegetable oil refining plant, vegetable oil refining plant manufacturers, oil refining plant manufacturer,Oil Refinery Machines

Our products include vegetable seeds oil mill, soya bean oil extraction machine, palm oil refining machine, sunflower oil making machine, cooking oil machine, edible oil refineries, corn germ oil processing plant, cotton seeds oil refinery plant.

Welcome to contact us any time!

http://www.oilgrainmachine.com

http://www.sinoder.com

Video of Vegetable Seeds Oil Press and Refining Plant:

https://www.youtube.com/watch?v=0ZgkOjcZ26I

Technical parameters

Vegetable Oil Refining Machines – Solution and Technology

FAQ

Can you send us your detail requirement?

What is your raw material? peanut,sesame,sunflower seeds, palm,soybean, olive?

How many oil material do you want to extract per hour?

Do you need the following crude Oil refinery process?

A,degumming & deacidifying section,

B.Solvent extraction section,

C. deodorizing section,

D. de-waxing section (special for sunflower seed and corn oil).

E. fractionation section(only for palm oil)?

F. Others?

What is your raw material? peanut,sesame,sunflower seeds, palm,soybean, olive?

How many oil material do you want to extract per hour?

Do you need the following crude Oil refinery process?

A,degumming & deacidifying section,

B.Solvent extraction section,

C. deodorizing section,

D. de-waxing section (special for sunflower seed and corn oil).

E. fractionation section(only for palm oil)?

F. Others?