Solution

Latest News

Vegetable Oil Process

Refined Oil Dry Fractionation Solution

We're here to help: Easy ways to get the answers you need.

Product Introduction

Type: fractionation of oil on basis of melting points

Processing Material: palm oil or other oilsMajor equipment: crystal jar, water-cooled screw chillers,membrane filter press

Application: new type oil fractionation technology applicable for palm oil, cottonseed oil, peanut oil, fish oil, chicken oil,algal oil, linseed oil. Palm oil fractionation technology adopts advanced palm oil processing technology of controlled cooling, crystallization, filtration and separation technology, obtaining palm oil with different melting points, like 33℃, 24℃, 18℃, 14 ℃,12℃,10℃,8℃,etc. This featured palm oil fractionation machine with fully computerized automation is featured by low investment, high liquid oil yield, high purity of solid fat, high profit etc.

Dry Fractionation Technology

The widespread use of the three oil modification processes - hydrogenation, interesterification and fractionation - extended the range of applications of the triglyceride oils. These processes principally serve the purpose of modifying the melting properties of oils and fats in order to improve their functional properties in specific applications, but the processes are also used to improve the stability of the oils and fats thus processed.

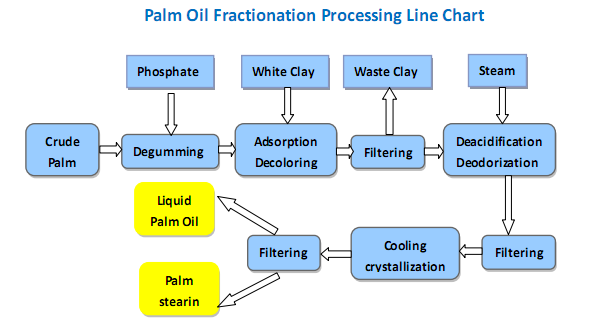

In edible oil processing, a fractionation process consists of a controlled cooling of the oil, thereby inducing a partial, or ‘fractional’, crystallization. The remaining liquid (olein) is then separated from the solid fraction (stearin) by means of filtration or centrifugation.

Natural oils and fats have different characteristics due to the fact that they are composed of a great number of different triglycerides. These contain fatty acids with carbon chins of different lengths and with different degrees of unsaturation.

Triglycerides with a high degree of unsaturation, indicated by a high iodine value, have a lower melting point than those containing more saturated fatty acids. If oil is cooled to a certain temperature, the high melting triglyceride (Stearin) will crystallize while the low melting ones will remain fluid. The stearin can then be separated from oil (Olein) by different methods and the fat/oil is thus divided into two fractions: Stearin with a high melting point and olein with a low cloud and melting points.

This technique is called fractional crystallization and used to obtain oils or fats more suitable for example, as cooking oils or for margarine/shortening production.

Palm oil is composed of triglycerides with a variety of melting points, which results in different melting point range of palm oil. Palm oil is divided into solid part and liquid part through utilizing different welding points and different solutions of various triglycerides composing oil.

On basis of difference of triglyceride properties, it creates related crystallization conditions so as to crystallize and separate from original solution with high purity. This process is called palm oil fractionation.

The liquid fraction (Olein) is used extensively as a liquid cooking palm oil in tropical climates. The liquid palm oil has competitive price with the more expensive groundnut, corn and sunflower oils.

Note:The folloing is just for reference.

- Palm oil fractionation is a kind of new oil processing technology.

- By using palm oil fractionation, the palm oil products of different melting points can be obtained, such as 8, 10, 14, 18, 24, 33, 44, 55 degree etc.

- At the same time, it can also be used to process cottonseed oil, fish oil, lard oil and other animal oil, which can greatly improve additional value of oil products, and increase economic benefits of the enterprise.

- Palm oil fractionation and production technology developed by our company is of advanced technology, full computer automatic cooperation, lower investment cost, high liquid oil yield, high solid fat purity and high economic benefit.

1) Cottonseed oil dewaxing

Cottonseed oil is one of the largest oil types, whose fatty acid is composed of 20%~22% palmitic acid, 30%~35% oleic acid, 40%~45% linoleic acid. The melting point of cottonseed oil is 10~15.6 °C. As the high-grade edible oil, cottonseed oil is not widely used in winter because of its easy turbidity caused by higher melting point, so its price is also low. By fractionation, liquid and solid oil can be obtained, which can increase oil' added value and edibility.

2) animal oil dewaxing , such as fish oil, lard oil, chicken oil etc.

With the fractionation, separate the white and transparent hydraulic oil from animal oil. The Cholesterol in fractionated oil is 50% less than that in crude oil, which greatly improves the nutritive value of animal oil and has a very high economic value.

3) separation of mixed fatty acids

According to the carbon chain length of fatty acids, separate short carbon chain (C12), medium carbon chain (C14) and long carbon chain (C16, C18) by vacuum distillation, and then separate the saturated fatty acid from the unsaturated fatty acid. Owing to the little boiling point differences between them, they can't be fully separated and also will has high production cost. Our company uses dry fractionation to separate the mixed fatty acids into various fatty acids of different melting point and application.

Technical parameters

FAQ

Relevant